MIL-P-18526A(SH)

4.2 Classification of inspections.

The inspection requirements specified herein are

classified as follows:

(a) Qualification (see 4.3).

(b) Tests (see 4.5):

(1) Shop tests. To be conducted on each pump supplied under the contract

or order (see 4.4.1).

(2) Performance evaluation tests. To be conducted on one pump of each class,

design, and size on each contract or order (see 4.4.2) .

(3) Design evaluation tests. To be conducted on-one pump of each class,

design, and size (see 4.4.3).

4.3 Qualification tests. Qualification tests shall be conducted at a laboratory

satisfactory to NAVSEC. Qualification tests shall consist of the tests specified in 4.3.1.

4.3.1 The following tests shall be performed in the order listed:

(a) Performance evaluation tests as specified in 4.4.2.

(b) Design evaluation tests as specified in 4.4.3.1 through 4.4.3.10.1.

(c) Maintenance engineering analysis shall be conducted in accordance with MIL-

M-24365.

4.3.2 Qualification shall apply separately to each class.

Qualification will include

all sizes for a specific class.

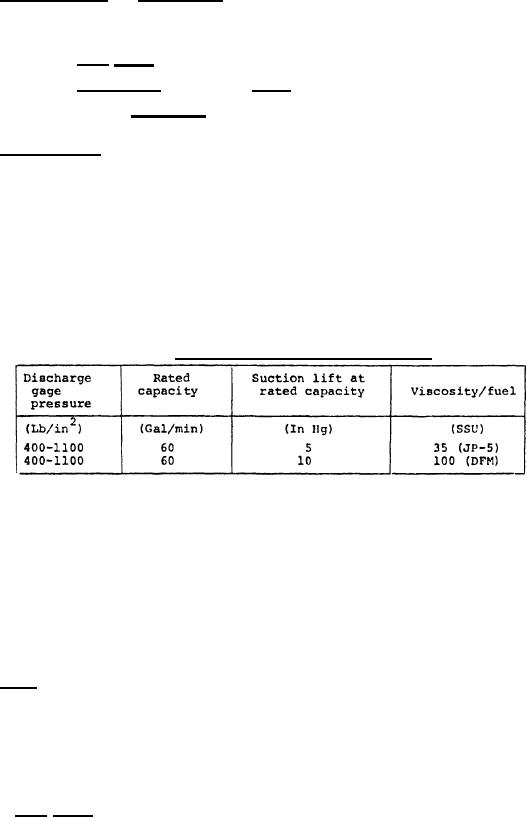

4.3.3 Pumps submitted for qualification tests shall have characteristic ratings of not

less than the values specified in table V.

TAELE V.

Qualification test characteristics.

4.3.4 Units submitted for qualification testing shall be operated at the maximum rub-

bing speed for which the unit is designed. Operating at a rubbing speed greater than that

at which the tested unit operated on qualification test, may require an additional test

subject to NAVSEC design review (see 4.4.2 . The test specified in 4.4.2 is intended to

demonstrate the reliability of the pump design.

4.3.5 Unless otherwise arranged between the Government and the contractor, the pump

submitted for the qualification testing shall be furnished complete with a prime mover and

necessary accessories. The prime mover need not be made to Government specifications.

Qualification of a pump will not include qualification of a driver.

4.3.6 The potential contractor desiring qualification of a specific pump class shall

submit drawings to NAVSEC for review as a prerequisite to the performance of the qualifica-

tion tests specified herein.

4.4 Tests. Failures, deficiencies, and discrepancies revealed during the performance

of the specified tests and the corrective measures taken shall be recorded and fully docu-

mented in the applicable test records and test reports. After correction of deficiencies,

tests shall be repeated to the extent necessary to ascertain acceptability of the modified

pump. Major failures indicative of the design deficiency (as distinguished from shop error

or faulty workmanship) shall be reported to the design review agency before a correction is

made. Except where specifically required herein to be tested with the actual driver, tests

may be conducted using a substitute driver, provided the actual driver separately passes

the tests required by its applicable specification.

4.4.1 Shop tests. Shop tests shall be performed on each pump being supplied (and sub-

components of each pump if applicable). Each shop test shall be fully documented by a pre-

scribed test procedure and a written record of the performance and findings of each test.

A compilation of the documentation of the shop tests performed on each pump shall be fur-

nished in duplicate to the cognizant Government quality assurance office and to the procur-

ing agency. The following shop tests shall be performed on each pump:

(a) Hydrostatic pressure test (see 4.4.1.1).

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business