MIL-P-17861F

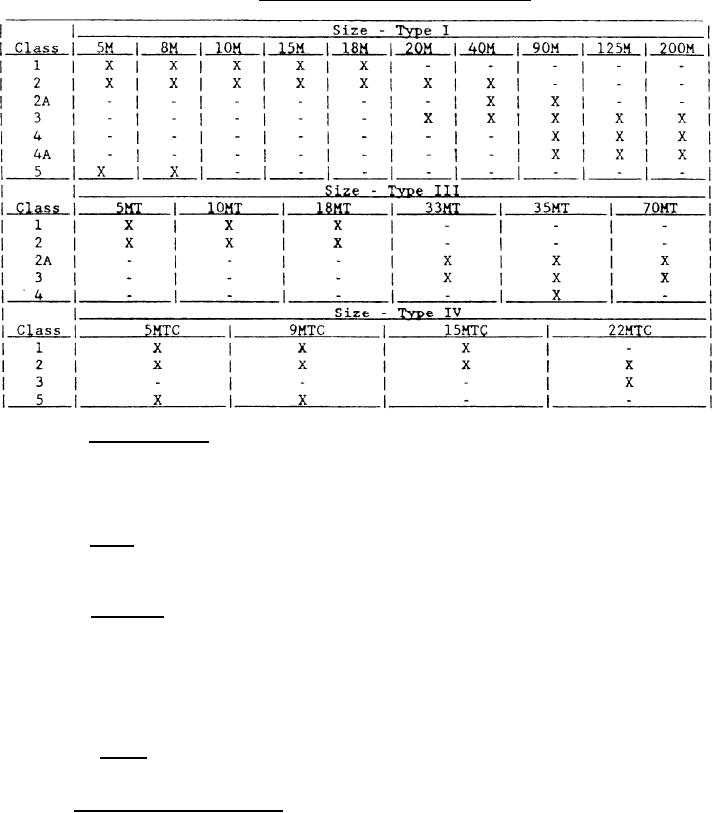

TABLE I. Applicablity of class to size.

3.4.1 Iron castings. Gray cast iron used for pump casing impellers, and

wera plates shall meet the requirements of ASTM A 48, class No. 25 or better, or

of ASTM A 126, class B or better. Ductile (nodular) iron of ASTM A 536, or

malleable from castings may be used in lieu of gray iron castings provided the

surface has a Brinell hardness number of not less than 160.

3.4.2 Steel. Steel used for such components as pump shafts, impellers, wear

plates, skids, bases, and diffusers shall be of a type and grade normally used

by the contractor on his standard commercial units.

3.4.3 Aluminum. Aluminum for pump casing shall be a silicon-copper-aluminum

alloy or a silicon-magnesium-aluminum alloy conforming to ASTM B 26/B26M for

sand castings or ASTM B 108 for permanent mold castings, as applicable.

Pressure-containing castings shall be heat-treated as required to produce a

tensile strength of not less than 30,000 pound-force per square inch (psi) .

Acceptable alloys shall include, but not necessarily be limited to, commercial

alloys 319.0 and 356.0.

3.4.4 Bronze. Bronze castings for pump impellers, when material B or D is

specified, shall be composition bronze (alloy 85-5-5) conforming to ASTM B 62.

3.5 Desire and construction. The pump unit shall be constructed to prevent

conditions hazardous to personnel or deleterious to equipment and shall permit

easy accessibility for maintenance and service in the field. The pump unit

shall withstand the strains, jars, vibrations, and other conditions normal to

shipping, storage, and installation; and shall be complete so that, when

installed, it can be used for any operation for which it was designed.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business